Reference: pages 31-06, 31-07, 42D-02, 42D-27 (rev 3); 5.0 hours

If you are following this blog for the RV-12 airplane you will notice I am jumping between sections. Last entry was dealing with wing attachment pins and todays with fuselage wiring. One way to sort out of this out is to use the index of pages off to the right on this page. That way it is easy to look up all the entires dealing with a single page.

Step 1: Install snap bushings in the F-1204C-L & -R Fwd Bulkhead Sides and F-1204B-L & -R Aft Bulkhead Sides.

Step 2:

Step 2: Choose one of the two ES RS 49-496 Reed Switches. Trim one of the two wires back to 4.5 inches in length. Strip the ends of both wires coming from each switch. To the 4.5 inch long wire crimp on a ring terminal.

Step 3:

Step 3: Using the hardware called out in figure 2 & 3 (on page 31-06) attach the ES RS 49-496 Reed Switches to the Arm Rests (attach the ring terminal from Step 2 at the same time). Align the inboard end of the switch with the inboard face of the armrest. Route the remaining wire on the right side of the aircraft and both wires on the left side of the aircraft through the snap bushings installed in Step 1. Crimp on butt splices to the switch wires.

Step 4:

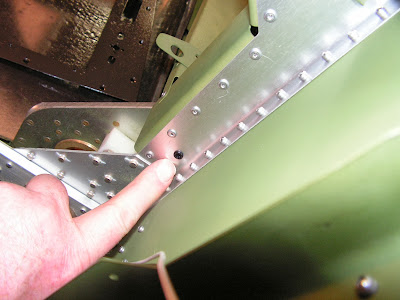

Step 4: To test the Reed Switches, temporarily connect a multimeter as shown by Van's Aircraft in figure 5 on page 31-06 by connecting one wire coming from the left reed switch to the positive multimeter lead and the remaining reed switch wire and negative multimeter lead to the fuselage frame (ground). Turn the multimeter to the continuity check mode. Snap the left Fuselage Pin Stopper into the Fuselage Pin Latch. The multimeter should indicate continuity. Repeat this step for the right reed switch.

When the stoppers are not latched there should be no continuity through the reed switch. If the stoppers are engaged and there is continuity, try moving the reed switches in or out. Be sure to check that if the stopper is not in the pin latch hole but under the pin latch there still should be no continuity. The only position that should create continuity is when the stopper is fully engaged in the pin latch holes!

It may be necessary to trim the WD-1217 tube. When installed, the top of the tube should be approximately centered on the reed switch. Remove the stopper from the fuselage pin and trim 1/32 of an inch from the top of the tube. Reassemble the fuselage pin with the stopper and test. Repeat as required. Do not remove more than 1/8 of an inch.

Builder's note: I ended up removing material from the left hand pin assemble and part of the rubber on the cushioned clamp to get it to work, while the right side worked the first time.

Step 5:

Step 5: Make WH-B167 (WHT) Spar Pin Interconnect Wire by cutting a 42 inch long piece of 22 gauge wire and striping both ends. Crimp one end to the butt splice installed in Step 3 on the right Reed Switch, route through the Wire Run Conduit and crimp the other end to one of the butt splices installed in Step 3 on the left reed switch. Crimp the remaining butt splice on the left switch to the WH-F50 (BRN/BLU) Spar Pin Wire.

Step 6:

Step 6: Double check that hardware installed in Step 3 is tight if altered when troubleshooting in Step 4.

This completes page 31-06.

Reference 31-07

Step 1: Route the wires of the WH-RV12-OPTIONAL harness (those coming out of the main 25-pin d-sub compactor but not attached to the AP-74 25-pin d-sub compactor) through the cushion clamp near the left ES CPU FAN and lower snap bushing in the Inst Stack Support. Separate the approximately 22 inch long WH-L80(YEL/PRP) and WH-L82 (YEL/GRN) wires from the harness.

Step 2:

Step 2: Route the remaining WH-RV12-OPTIONAL harness through either of the snap bushings in the forward center region of the Panel Base leaving 31.5 inches (

BUILDER'S NOTE: This length will be changed with the update of the SkyView in a later blog entry) to the main d-sub above the panel base. Tape the optional harness down so that this distance does not change as you route wires.

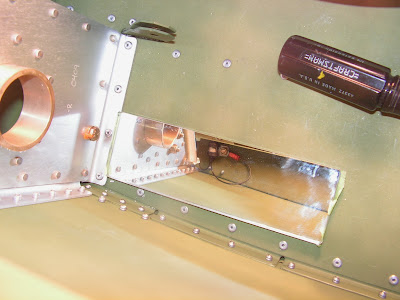

Step 3: If installing the optional autopilot, use a unbid to enlarge the hole for the auto disconnect switch to 1/2 inch diameter in the F-1202A Instrument Panel for the button in the WH-RV12-APDC Autopilot Disconnect. Install the autopilot disconnect as shown in figure 1 of the RV-12 aircraft plans on page 31-07.

BUILDER'S NOTE: The disconnect switch has been updated to include a molex connector in the wiring. See page 42D-02 and 42D-27. Most of page 42D-02 does not apply to my airplane because I had not installed the Dynon DEK 180 previously.

Reference: 42D-02, Step 26:

BUILDER'S NOTE: The disconnect switch has been updated to include a molex connector in the wiring. See page 42D-02 and 42D-27. Most of page 42D-02 does not apply to my airplane because I had not installed the Dynon DEK 180 previously.

Reference: 42D-02, Step 26: Label then cut the wires coming from the WH-RV12-APDC Autopilot Disconnect six inches behind the Instrument Panel. Remove the autopilot disconnect and set aside for later.

Reference: 42D-27

Step 1:

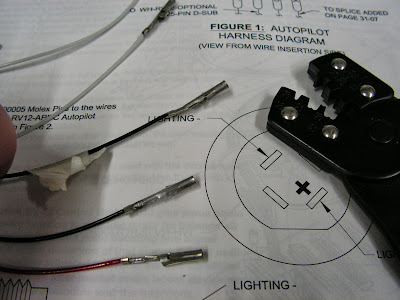

Reference: 42D-27

Step 1: Find the wire previously cut in page 42D-02, Step 26 for the WH-RV12-APDC Autopilot Disconnect that are still attached to the fuselage. Crimp ES-00006 Molex Socket to the end of each of autopilot disconnect wires. Insert each wire into a ES-00007 Molex Receptacle as shown in figure 1 on page 42D-27 of the RV-12 airplane planes.

Step 2:

Step 2: Crimp ES-00005 Molex Pins to the wires coming from the Autopilot Disconnect switch.

Step 3:

Step 3:Enlarge hole to 1/2 inch in Instrument panel.

Builder's Note: This was done previously. There are some repeated steps from section to section.

This completes page 42D-27

Back to Reference: page 31-07

Step 4:

This completes page 42D-27

Back to Reference: page 31-07

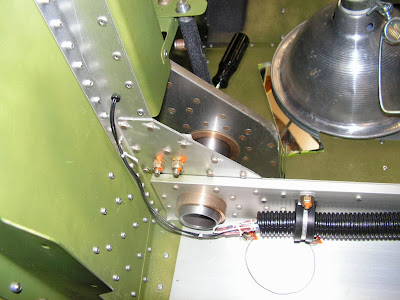

Step 4: Route all the wires coming from the back of the WH-RV12-APDC Autopilot Disconnect up through one of the two snap bushings in the Panel Base.

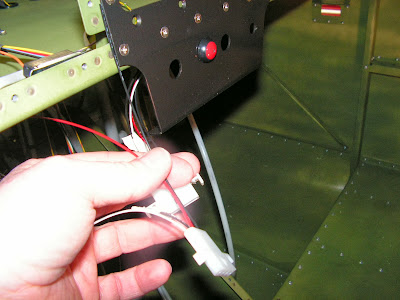

Crimp together into the same side of a butt splice the red wire coming from the autopilot disconnect WH-F177(RED) and the WH-L80 (YEL/PRP).

Step 5:

Step 5: Make a WH-B179(WHT) Cockpit Light Power Wire and WH-B180(WHT) Cockpit Light Ground Wire by cutting two pieces of 22 gauge wire 153 inches long.

BUILDER'S NOTE: This is the method I used, however there is an alternative way of wiring the light in section 42D.

Step 6: Crimp the WH-B179(WHT) Cockpit Light Power Wire into the open end of the butt splice with the WH-L80(YEL/PRP) and WH-F177 (RED) wires crimped in the other end.

Step 7: Crimp the WH-B180(WHT) Cockpit Light Ground Wire into the open end of the butt splice with the WH-L82(YEL/GRN) and WH-F178(BLK) wires crimped in the other end.

Step 8:

Step 8: Route the WH-B179(WHT) Cockpit Light Power Wire and WH-B180(WHT) Cockpit Light Ground Wire along the route of the Wh-Q54(ORN/BRN) Fuel Level Wire. Cover the ends of the wires to prevent them from shorting out to the aircraft structure then coil the extra wire for later use. See page 31-05.

Step 9:

Step 9: Route the longer WH-F78(WHT) and WH-F79(BLK) wires coming from the back of the WH-RV12-APDC Autopilot Disconnect back through the lower snap bushing in the Ins Stack and cushion clamp near the lest ES CPU FAN.

Step 10:

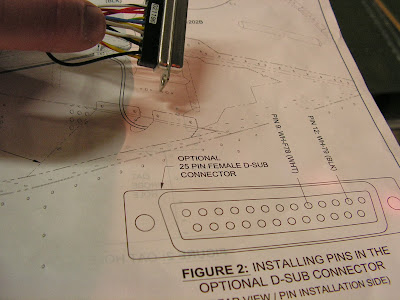

Step 10: Remove the d-sub backshell from the main 25-pin d-sub connector on the WH-RV12-OPTIONAL harness. Insert the pins on the ends of both WH-F78(WHT) and WH-F79(WHT) wires through the heat shrink and into the correct pin locations as shown in figure 2 on page 31-07 in the 25-pin d-sub female connector. Check with a gentle tug that each wire has snapped into place. Slide the heat shrink supplied with the optional harness up the wires until its length is centered about the exit of the backshell then activate the heat shrink.

Builder's note: I did not shrink the heat drink tubing as directed above. There are still wired that will need to be added and subtracted because of the Dynon SkyView update.

This completes page 31-07. There is a lot to digest and a lot of jumping around because of the updates. Most of this will become an academic discussion as the newer wiring harness are provide by Van's Aircraft. But for those who got caught in the middle of the updates this is reality!