Today I installed the largest Koger sunshade available for Van's Aircraft for the RV-12 airplane. Also, it is time for Ernie's to do the next EAA technical inspection of the RV-12.

Next came my next inspection of the RV by one of our EAA chapter's tech counselors. Overall he has been and is pleased with my RV-12. There were a few items he wanted to be see addressed as listed below and how they were corrected or addressed.

Prop bolts too short (pictured below). Fixed: Contacted Van's and Sensenich Propellor. I was told by Sensenich that these are the correct bolts despite two threads not showing beyond the lock nut (an industry standard.) Their explanation is there are Nor-lock washers under both the head and the nut. I also received an email from Sensenich's engineering stating that this is the correct installation and that it isn't possible to go to longer bolts. A copy of this email will be saved in my maintenance files.

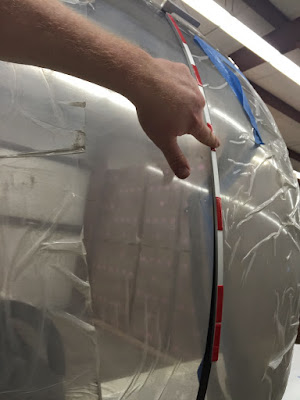

Aileron's need to be set 3/32" below the trailing position (on each side) when the stick is in the neutral position. Not raised slightly as mine were. See picture below of wrong setup. No picture of corrected setup. Fixed: Crawled back into the baggage area and readjusted the push rods ensuring there was enough threads still in the push rods. Total adjustment was 1.5 turns on the push rob ends. Re-torqued the push rod ends. Note: Van's Production Acceptance Criterial calls this out on page G2-2.

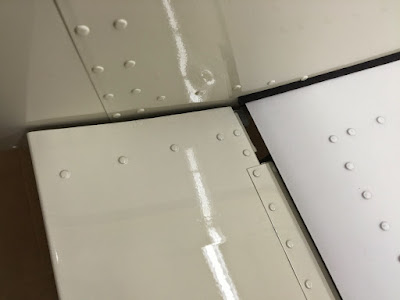

Clearance of rudder cables was not acceptable on the rear tailcone former. See pictures below. Fixed: enlarged openings, deburred and primed edges.

Safety wire all hose clamps. Not called out in plans but it is one of Ernie's personal preferences. Fixed; Safety wired all the hose clamps.

Clearance for the flaperon servo linkage in the tailcone needed to be increased. Fixed by increasing the hole size in the fiberglass tailcone.

Additionally I installed the zip ties on the brake lines. Oh yes, we also found a leak in the left brake line/landing gear block that is now fixed.

That is all for this entry. Next I have some touch up of the primer on the wings and top coating of these ( this will be included in the painting entry). And then updating of the Skyveiw EFIS system.