Reference: page 37-05 revision date 11/21/11; 8.0 hours

Today's entry is split between revision 11/21/11 for steps 1-8 and 09/30/09 for steps 9-11. This is due to my kit coming with the older style fuel tank that requires cutting of the fuel tank filler hole. But it is all good!

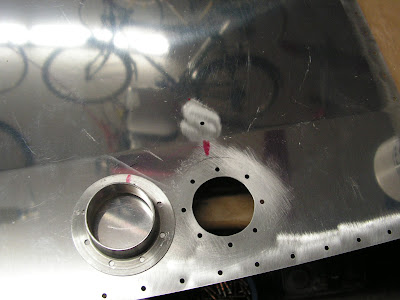

Step 1: Remove the vinyl protective covering from both sides of the T-1210 Fuel Window, then deburr the edges.

Step 2: Use a toothpick to thinly coat the surface under the head of all the screws that will be used in installing the T-1210 Fuel Window with fuel tank sealant.

Step 3: Install two screws into the T-1201 Main Tank Skin in the locations called out in Figure 1. Tape over the screw heads to hold them in place then tip the tank on its side with the screw heads against a flat surface.

Step 4:

Step 4: Apply a thin layer of tank sealant along the perimeter of the T-1210 Fuel Window on one side.

Step 5: Apply a thin layer of sealant to the flanges of the T-1213-1 Backing Plate then carefully place the backing plate onto the side of the T-1210 Fuel Window without fuel tank sealant. Reach into the tank and slide the assembly in place over the two screws, then tip the tank upright.

Step 6:

Step 6: Insert the rest of the screws into the remaining holes attaching the T-1210 Fuel Window. Remove the tape from the two screws used as guides.

Step 7: Install the washers and nuts that attach the T-1210 Fuel Window and T-1213-1 Backing Plate to the T-1201 Main Tank Skin finger tight. Cover the nuts with fuel tank sealant. If using a nut driver to hold the nuts do not tighten the nuts using the handle. Tighten with the shank using fingers only.

NOTE: Do not attempt to remove any sealant squeezed out at the sight window holes until it is fully cured.

Step 8: Cut the end off of a popsicle stick so it is straight rather than round, then bevel the edge so it can be used as a scraper.After the sealant has cured use this tool to remove any sealant that may have oozed out of the sight window holes.

Reference: page 37-05 revision date 09/30/09; 1.0 hours

The newer RV-12 aircraft kits don't follow these next steps!!!

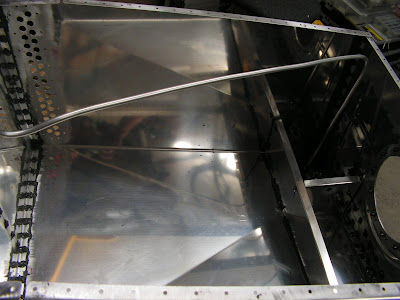

Step 9: Place a blanket or large rag over the inside bottom of the fuel tank to collect drill chips from following steps. Cleco the T-1204A Top Tank Skin to the Fuel Tank Assembly.

Step 10: Layout and drill #30 a hole pattern in the flange of the T-1204B flange per dimensions given by Van's Aircraft.

Caution: Avoid deforming the Fuel Neck and Fuel Flange when tightening the hose clamps.

Step 11:

Caution: Avoid deforming the Fuel Neck and Fuel Flange when tightening the hose clamps.

Step 11: Use two hose clamps and the T-1212 Fuel Neck Collar to join the T-1211 Fuel Neck and Flange together per the dimensions call out by Van's Aircraft on page 37-05 of the plans.

This completes page 37-05.

This completes page 37-05.

Reference page 37-06 rev 1 dated 02/22/10

Step 1: Temporarily bolt the Fuel Tank to the Center Section Assembly and the Attach Angle using hardware called out by Van's Aircraft.

Step 2:

Step 2: Center the Filler Neck Assembly on the skin fuel opening. For the best fit of the Filler Neck Assembly(between the Fuel Tank Assembly and the Turtle Deck Skin) it may be necessary to adjust the length by loosening the hose clamps and extending or shortening the assembly. Bend the upper flange of the Fuel Neck as required for at he best fit against the fwd turtle deck skin (small gaps will be filled with fuel tank sealant.)

Step 3:

Step 3: Once satisfed with the postion of the Filler Neck Assembly, match drill #30 the holes in the Fwd Turtle Deck Skin into the flange of the Fuel Neck, cleco as you go. Trace a circle onto the Top Tank Skin around the edge of the Flange. Remove and disassemble the Filler Neck Assembly. Remove the fuel tank from the fuselage.

Step 4:

Step 4: Position the Flange on the Top Tank Skin, centered in the circle from Step 3. Match-drill #30 the holes in the flange into the top tank skin, cleco as you go. Trace a circle onto the Top Tank Skin around the inside of the flange. Mark the rotational position of the flange. Remove the flange and the top tank skin.

Step 5:

Step 5: Remove the material, marked with the inner circle from the Top tank Skin. Deburr the top tank skin and the Fuel Neck. Prime the outside of the fuel neck and Flange ONLY!. Remove any debris from the inside of the fuel tank.

Step 6:

Step 6: Fabricate two T-1216 Clips per Figure 2 on the RV-12 plans page 37-06.

Step 7:

Step 7: Fabricate the Fuel Return Line per plans. Install a nut and sleeve on one end of the fuel return line and flare that end. From the bulkhead fitting, route the fuel return line with the clops and rivet the clips to the top tank skin.

Step 8:

Step 8: Rivet the Top Tank Skin to the Fuel Tank Assembly per the call-out. Rivet the Flange to the top of the Fuel Tank Assembly. Install the Fuel return line to the bulkhead fitting.

Step 9: Add sealant in any remaining areas, corners cracks and crannies as necessary. Install the Res Sender Plate and Sending Unit with sealant using the hardware called out on Page 37-04. Use 1/16 inch thick layer of sealant between the Res Sender Plate and the Fwd Tank Bulkhead and in place of the IE F-385 Gasket. Tighten screw just enough to cause sealant to bulge evenly from under the perimeter of the sender plate.

This completes page 37-06. Again my plans and kit, because of revisions, is split between two sets of plans. Hopefully this is not too confusing.I'm going to let the tank sit and the sealant to harden before moving on with this section and the pressure test.

This completes page 37-06. Again my plans and kit, because of revisions, is split between two sets of plans. Hopefully this is not too confusing.I'm going to let the tank sit and the sealant to harden before moving on with this section and the pressure test.