Reference: Pages 31A-07, 31A-08; 2.75 hours

Vans Aircraft has updated the wing to fuselage electrical interconnect for the RV12 airplane. I touched on it in the other entry for today. You will noticed I started in the middle of the section this is because my wing for the RV12 are in storage, so I will need to plan the update for the wings at another time.

Also I am including a head scratcher on the Builder's Gotcha list. One of the wires has been changed to a new part number but the drawings in the plans don't reference it. The new wire is WH-L458 and is discussed later in this entry in more detail. The drawings in question are on page 42D-23 and 31A-07.

Step 1: NA as they were not installed Remove the F-1270B ASSMY from the left and right Side Skins.

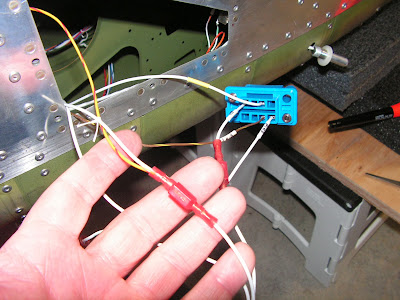

Step 2: Label all the wires for the wing connections.

Builder's note: I used heat shrink tubing and marked it with a Sharpie before shrinking it.

Steps 3, 4, & 5 Builder's note these steps didn't apply as this was new construction on the RV12 airplane.

Step 6:

Builder's note: I used heat shrink tubing and marked it with a Sharpie before shrinking it.

Steps 3, 4, & 5 Builder's note these steps didn't apply as this was new construction on the RV12 airplane.

Step 6: Crimp an ES-00079 Floating Connector Pin 16-20 AWG on all the wires in Step 5. This is the WH-F57 (BRN/YEL) Stall Warn Wire, WH-L73(YEL), WH-L88(YEL/BLU), and WH-B183 (WHT) Wing Ground Wires. See figure 2 & 3 on page 31A-07 of the RV12 aircraft plans.

Step 7:

Step 7: Insert the pin on the WH-B183(WHT) Wing Ground Wire into position 1 on the back of the Floating 8 Pos Connector Female.

Step 8:

Step 8: Insert the pin on the WH-F57 (BRN/YEL) Stall Warn Wire into position 2 on the back of the ES-00077 Floating 8 Pos Connector Female.

Step 9:

Step 9: Insert the pin on the WH-L88(YEL/BLU) into position 4 on the back of the ES-00078 Floating 8 Pos Connector Male.

Step 10:

Step 10: Insert the pin on the WH-B183(WHT) Wing Ground Wire into position 1 on the back of the ES-00078 Floating 8 Pos Connector Male.

Step 11:

Step 11: Insert the pin on the WH-L73(YEL) into position 5 on the back of the ES-00078 Floating 8 Pos Connector Make.

This completes page 31A-07.

Reference page 31A-08

Steps 1 - 6 D180 Builder's note: As I am not installing a Dynon D180 These steps do not apply to my Rv12 airplane.

Step 6:

This completes page 31A-07.

Reference page 31A-08

Steps 1 - 6 D180 Builder's note: As I am not installing a Dynon D180 These steps do not apply to my Rv12 airplane.

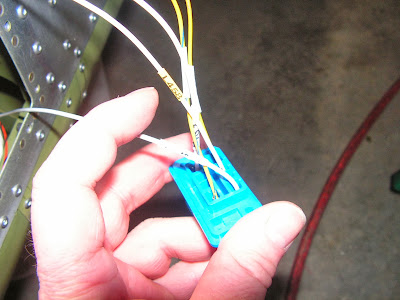

Step 6: (SV-D1000) EFIS: Insert the pin on the WH-274 (WHT) Lighting Power Update Wire into position 8 on the back of the ES-00077 Floating Connector Female.

Step 7: Was complected previously.

Step 7: Was complected previously. Cut the spade terminal off the WH-B184(WHT) and strip the wire. Crimp on a pin to the WH-B184(WHT) Nav/Strobe Power Wire.

Step 8:

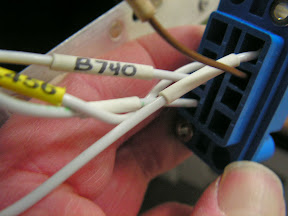

Step 8: Fabricate the WH-B740(WHT) Strobe Sych Wire by Cutting a 57 inch long piece of 18 AGW wire. Strip the ends of the wire and install an ES-00079 Floating Connector Pin on each end.

Step 9:

Step 9: Insert the pin on one end of the WH-B740(WHT) wire into position 7 on the back of the EF-00077 Floating 8 Pos Connector Female.

Route the WH-B740 (WHT) wire across the fuselage following the same routing as the WH-B184(WHT) wire.

Insert the pin on the free end of the WH-B740 (WHT) wire into position 7 on the back of the ES-00078 Floating Connector Make.

Builder's note: Here is the Gotcha. Page 42D-23 in the plans Step 3 talks about wire number L458 being inserted into position 6. However the drawings all show the old wire number B268 on both sides of the fuselage as being inserted into position 6. No big deal just leave you wondering for a while!

Builder's note: Here is the Gotcha. Page 42D-23 in the plans Step 3 talks about wire number L458 being inserted into position 6. However the drawings all show the old wire number B268 on both sides of the fuselage as being inserted into position 6. No big deal just leave you wondering for a while!

Builder's note: Also there is no mention in the direction to ground the Noise Filter other than as a note on a drawing on page 31A-08. So I went ahead and ground it to the seat frame as pictured below.

Builder's note: Also there is no mention in the direction to ground the Noise Filter other than as a note on a drawing on page 31A-08. So I went ahead and ground it to the seat frame as pictured below.